A Sense of Belonging at Productronica 2025

I have just returned from my third visit to Productronica since the business was founded and I felt so much more at home than my first visit a decade ago.

- Hermes Version 1.7

- Exhibiting at the Show

- Meeting Customers

- The Hermes Standard Supervisory App

- Trade Media Interview

- My Takeaways

Productronica occurs every two years but I have skipped a few due to the Pandemic in 2021 and to attend other shows such as the Smart Factory Expo in 2017 and Apex Expo in 2023.

My first visit in 2015 was a fact finding expedition of the industry.

Industry 4.0 had just been coined a few years earlier so I was in a discovery phase to see if it would be a good time to start a business. My questions to machine builders were simple, where is your data? and how do I get hold of it?

The business was formed in 2016 initially creating what would become MultiPlug trying to provide a tool for machine builders to migrate their desktop applications to the (web) browser.

This would initially be operating on-premise, on-machine, on the int'ra'net, with future connections to what we now call the Edge.

The intention here was to act on our mission statement of Connecting Manufacturing with the Digital Economy - ie, if we use the same technology we can communicate with and pull in talent from outside our industry to resolve the recruitment issue of what would be called the Silver Tsunami.

However, the Hermes Standard was released a year later so instead we decided to eat our own dogfood and focused on creating our retrofit SMEMA Hermes Adaptor.

Hermes Standard Version 1.7

The arrangements for the 15th Hermes Standard Initiative meeting were made after I had planned my travels to Productronica so I listened to the meeting during my transfer at Heathrow Airport.

I had attended the New IPC Hermes Task Group back in October in Munich, so I was already informed why 1.7 still hadn't been published since being voted for in November '24.

Long story short, people were busy and the publishing schedule is now in the control of the IPC and the Task Group meeting was scheduled a year later.

The positive of this situation is more got put into 1.7 and members are generally in favour of more changes per version rather than the slow drip drip that reflects our twice yearly meetings.

The version numbers are starting to become a marketing issue as the number is more of a document number rather than a feature set. Lots of features are optional, so to not support newer versions handicaps the entire SMT production line.

We suggest to Machine Builders to support at least Hermes 1.5 of the BoardAvailable message so no data is lost between machines.

This does not mean you need to support all the new features of 1.5 or newer.

There is a workaround in this situation, which is to use the QueryWorkOrderInfo message on the next machine if a Supervisory System is being used.

The Hermes Standard Committee

Exhibiting at the Show

I was pleasantly surprised to be contacted by an Italian reseller in October stating they intended to feature our Adaptors on their stand. They have had sales success over the years building up the customer base in Italy and becoming our unofficial distributor and deployment expert in their region.

Some customers like to buy direct from us, others like to buy via a business local to their Country or they already have an relationship with.

They have recently been working with Honeywell retrofitting Hermes on to their existing Conveyors and Laser Markers.

They requested a short promotional video which we supplied but this meant that for the first time the Adaptors were at the show in an official capacity.

This is something we could have never had funded ourselves so we are very grateful to Mancini Enterprise Group for offering this to us.

Meeting Customers

Since our founding we have been a Digital First business that trades via ecommerce. This works for a lean Scaleup business but it also came from a principled point of view and observing the industry that to create Sales and Customer Support teams would eventually create bloat that would slow our business growth. You increasingly see self-service in the consumer world.

Our Industry has a heavy support culture and customers would happily pay for us to hold their hands but this can deskill our customers' staff and reduces the time our staff can support other customers. We feel that in-person support just doesn't scale and instead we support using digital methods. We are also lucky that our products are small so can be shipped worldwide for low cost and software support mechanisms have been designed since day one and not as a side thought.

The downside is we only make relationships with our customers by email and that's only if they request feature improvements.

It was very warming for some of our customers to reach out to me to arrange to meet at Productronica.

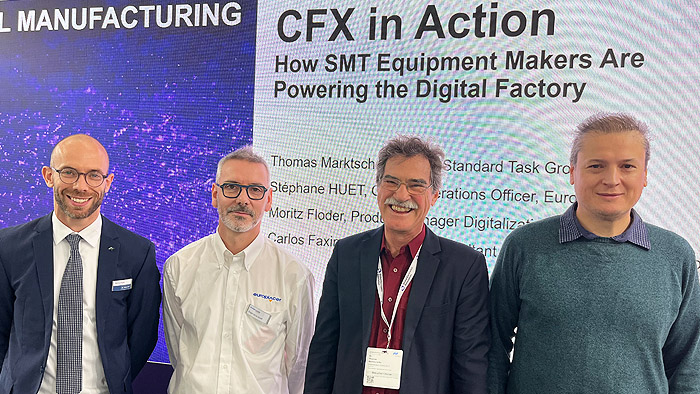

Daniel Odermatt from Siemens gave a presentation on the Global Electronics Association stand about their success story using Hermes and the CFX which used our Hermes Adaptor at the start of the line on the Laser Marker.

The Adaptors often are used to inject and extract Hermes data for use on existing equipment that only needs one data property of the Standard.

One memorable evening was when Haakon-Christian Oehninger-Storvoll from AXXE invited me out into Munich to join him at the end of a meal organised by ASMPT.

He was able to network me with other users of Hermes such as Per-Johan Edgren from TYRI who was already developing in-house Supervisory Software. AXXE uses 10 of our Adaptors to retrofit their entire production line.

ASMPT customers have been big users of our Adaptors and I thank their staff for spreading the word because we have no official partnership, and being very welcoming to me during the show.

The Hermes Standard Supervisory App

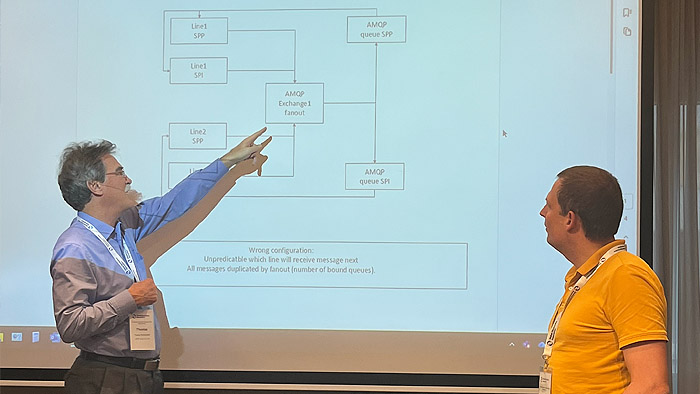

We used the show to launch the development of our Supervisory App for the Hermes Standard. The standard offers a set of messages targeted at PCB Board tracking and Work Order management.

These are sent via what is known as the Supervisory Channel which is a separate Network Socket connection to the equipment.

The Connected Factory Exchange (CFX) has similar functionality and was created after the Hermes Standard. The CFX would have been a better candidate for connections with vertical factory systems however the PLCs that the Board Handing equipment use don't or can't support the CFX.

Traditionally there would be middleware operating between the shop floor and the Manufacturing Execution Systems (MES) however the new data standards are often making these redundant.

Watch: CFX in Action 1. Europlacer 2. Kurtz Ersa 3. ASMPT

In fact the creation of the CFX was to define the 'last' connection type needed within the SMT factory. I feel in practice this middleware layer will continue as it describes who owns and manages what.

This explains why the MES software suppliers have been slow to support native connections to the Hermes Supervisory Channel. Another reason would be that Hermes was developed by machine builders, leaving software suppliers out of the loop.

Still, we waited and waited and our emails were unanswered by the MES community of whether they would support Hermes. After being asked by many customers over the years, including machine builder Europlacer, we finally decided to commission our own App.

Unlike the machine builders, those of us who work in the software industry don’t want to reinvent the wheel by creating duplicate software. Instead we enjoy collaborating on open source projects that will benefit the community.

Our own MultiPlug Hermes Extension can run independently of our Adaptors which means OEM Machine Builders can now upgrade to Hermes with little integration after a small fee.

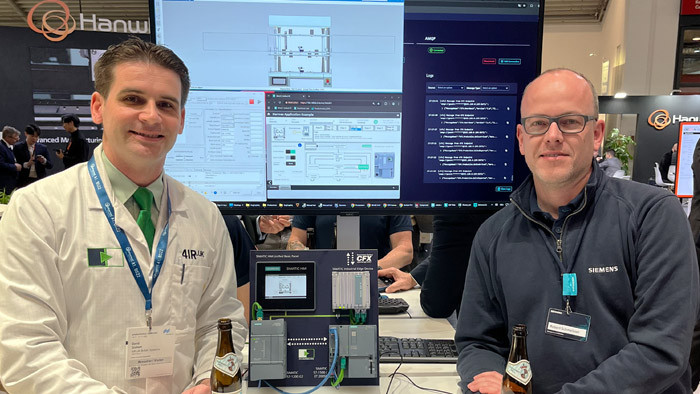

It was in the spirit of collaboration and community that Robert Schmeißer from Siemens invited me to share a beer on his stand to show off their Hermes solutions and discuss our Supervisory App.

He introduced me to their ecosystem and distribution platform that could host the App. I was pleased to see they were also using our Royalty Free CFX Logo to avoid the copyright issues we had in the past.

Trade Media Interview

During the last day I was finally able to introduce myself to Philip Stoten, founder of communications agency SCOOP. I have been watching Phil's content on YouTube since I joined the industry back in 2006 and for many years it was my only insight of how the industry was changing.

By this point of the show my takeaway was the need to relight the fire of promoting Hermes and the CFX and more importally the success stories of them that are happening under the radar of the management.

Philip often focuses on the C-Suite so it was good to talk about what was happening on the shop floor.

I did this in memory of previous CFX Chairman Michael Ford who unlike me was a great communicator and his void still needs to be filled. We also spoke how the industry has and hasn't progressed towards Industry 4.0.

Watch: Philip Stoten interviews David Graham on EMS @ C-Level

My Takeaways

- My white branded ESD coat really did make me stand out in the sea of blue suits at the show :)

- There is a desire to collaborate within the software community that are removed from the machine builders and MES suppliers (Integrators).

- Some machine builders believe they will only support Hermes version 1.2 and they need more encouragement to support 1.5 or newer to transfer the full dataset.

- Some machine builders are having difficulty justifying Hermes software development on their machines when they are already heavily embroiled with CFX developments focusing at higher tier customers.

- There is a big need to ramp up the awareness of progress of the Hermes Standard and the Connected Factory Exchange (CFX), this can be achieved in multiple ways ;

- The Global Electronics Association should survey the Industry using very detailed questions to machine builders and end users of what they support and how they are using the standards.

- Hermes End Users should be encouraged to join the IPC-HERMES-9852 Standard Task Group to share knowledge with the community.

- We should create Hermes Standard 'Success Stories' which can be used internally for our marketing purposes but also to support promotion generally.

- Machine Builders should be encouraged to join the IPC-HERMES-9852 Standard Task Group to bring the two communities together and use the communication tools offered by the Global Electronics Association.

- There have been a lot of personnel changes throughout the life of both the Hermes Standard and CFX, ranging from resignation, retirement and even death. From my point of view we should act to strengthen the governance and communications of both Standards.

About 4IR.UK British Systems

We are a Smart Factory solutions provider for the SMT Electronics Assembly manufacturing industry. We were founded in 2016 after the support of a seed funded Business Accelerator. We create retrofit hardware Adaptors that operate in more than 27 countries that extend the life of SMEMA based manufacturing equipment by providing solutions for production monitoring and supporting data connections to the Hermes Standard and the Connected Factory Exchange CFX. We also develop Software Extensions for the Low-Code No-Code MultiPlug Edge Computing Platform. The flexibility of off-the-shelf software combined with inside industrial experience means that 4IR.UK is ideally placed to anticipate and respond to a factory's changing needs.